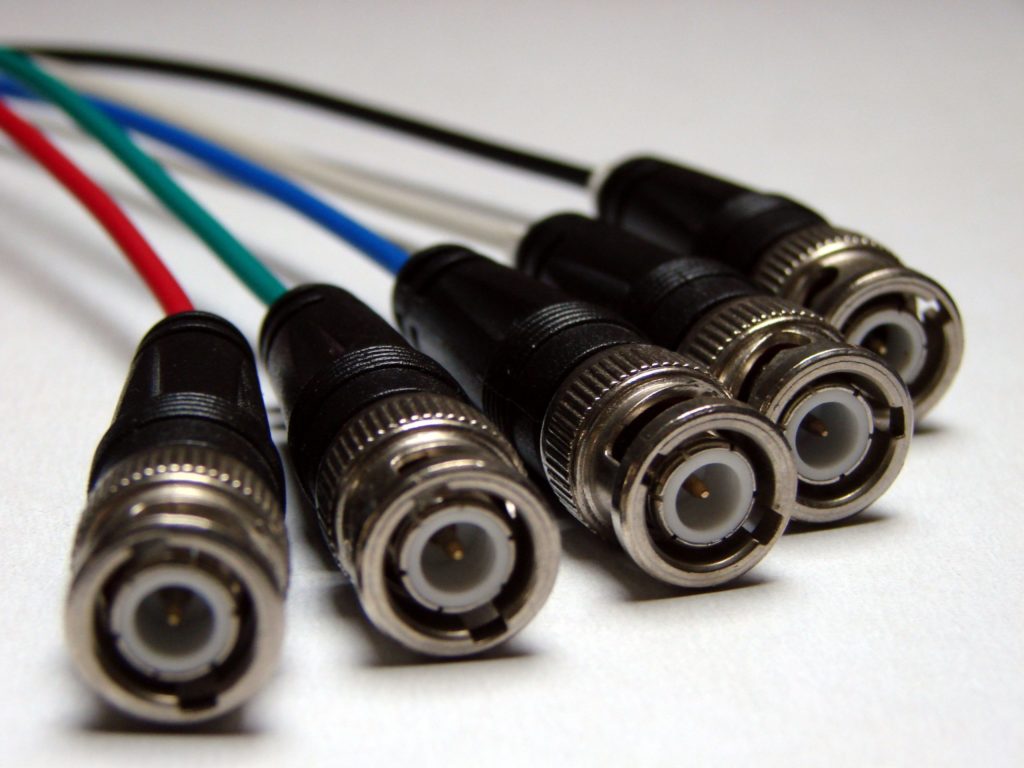

Connector manufacturers provide a vast array of product configurations since they serve many different industrial sectors. Performance requirements related to applications range from medical to industrial equipment, or automotive and aerospace sectors.

Requirements for finished cable assemblies often translate into small batch production tasks that complement the supplier’s main business focus. Turning to a specialized contract assembly supplier like Axcesor provides a highly manageable solution since the company’s core business is custom small and medium batch manufacturing and assembly.

Exemplifying this kind of relationship, one of Axcesor’s clients specified a broad line of specialty connectors. The client requested complete cable assemblies defined by 28 different styles each having a different length. In addition, each assembly may be fitted with up to 16 separate connector types.

Axcesor established an in-house assembly area with inventory so that each cable and connector type is on hand at any given time. When an order is received, cables are stripped by hand or with semi-automated stripping technology. Connectors are then soldered to cables and assembled.

Line clearance and quality control are crucial due to the common appearance. Each cable assembly is 100% tested for continuity and shorts, inspected for cosmetic defects, tied with cable wraps and shipped.

Axcesor provides value by shipping as little as a single cable or as many as 500 at a time.

Axcesor has experience terminating Fischer, ODU, Omnetics, NorComp, Nicolay, Lemo and other brands, and provides services to distributors, OEM’s laboratories, and end users.